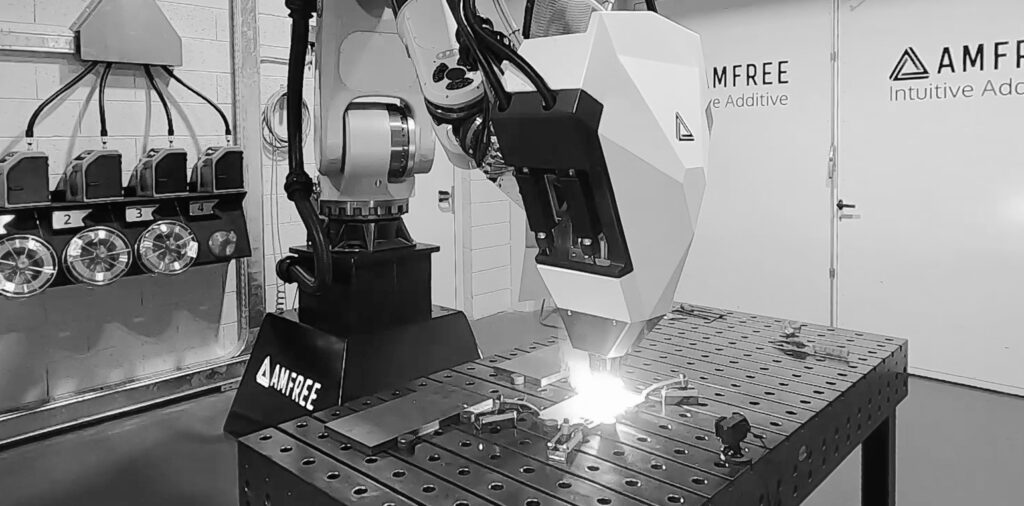

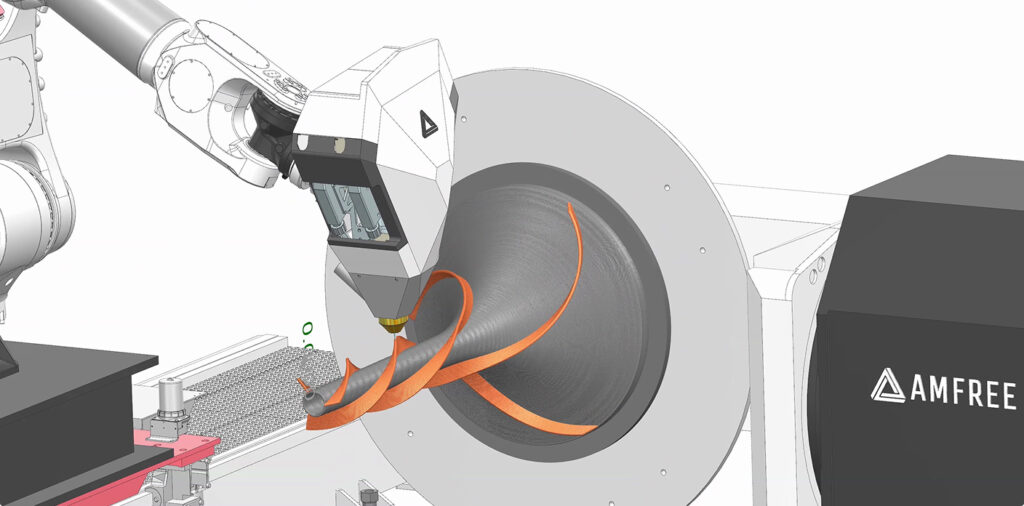

AMFREE’s Service Centre simplifies the use of large-scale metal additive manufacturing. Our technology providing you the most productive, qualitative and cost-efficient solution on the market.

Level 1

Initial training for new customers

Level 2

Advanced training for users

Level 3

Expert training